Crash worthiness restoration goes beyond cosmetics, focusing on stringent safety standards post-collision through structural integrity checks, precise alignment, and accurate auto glass replacement. Professionals require specialized training, protocols, and advanced tools like 3D laser scanners and CAD software to achieve meticulous precision, ensuring vehicles return to pre-accident condition with seamless panel alignment and consistent weld quality. Safety is paramount; thorough quality assessments using non-destructive testing methods verify structural integrity after repairs, providing car owners peace of mind on the road.

In the realm of automotive safety, ensuring crash worthiness is paramount. When undertaking restoration work, precise monitoring of accuracy is essential to maintain vehicle integrity and protect lives. This article delves into the critical tools and techniques for evaluating crash worthiness during repairs. From understanding stringent restoration requirements to employing advanced technology for accuracy tracking and quality assessment post-restoration, this guide equips professionals with knowledge to enhance safety standards.

- Understanding Crash Worthiness Restoration Requirements

- Essential Tools for Accuracy Monitoring During Repair

- Ensuring Safety: Techniques for Quality Assessment Post-Restoration

Understanding Crash Worthiness Restoration Requirements

The process of crash worthiness restoration goes beyond mere visual repairs; it’s about ensuring a vehicle meets stringent safety standards after a collision. This involves meticulous attention to detail, from structural integrity checks to precise alignment and, critically, accurate auto glass replacement. Every component must be reassessed to guarantee it functions optimally in the event of another impact, making crash worthiness restoration a complex yet vital process for any vehicle, especially premium brands like Mercedes Benz.

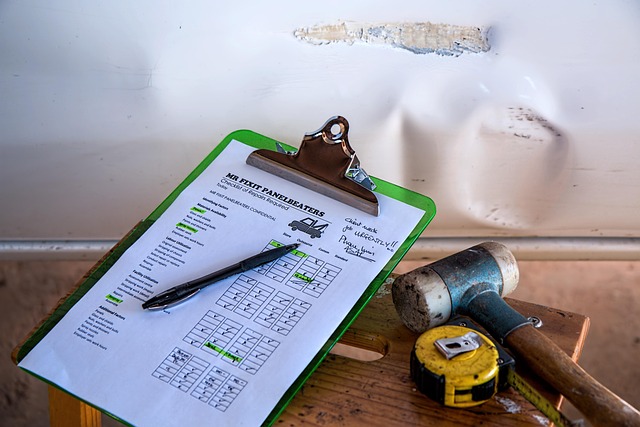

For collision repair professionals, understanding these requirements is key. It necessitates training and adherence to specific protocols, including the use of advanced tools that monitor accuracy throughout the restoration process. Whether handling a Mercedes Benz collision repair or general auto glass replacement, ensuring every part is precisely fitted and aligned is non-negotiable for maintaining crash worthiness.

Essential Tools for Accuracy Monitoring During Repair

In the realm of crash worthiness restoration, achieving precision is paramount to ensure vehicles return to their pre-accident condition. Essential tools for monitoring accuracy during this critical process include advanced measurement devices and specialized software. 3D laser scanners, for instance, provide detailed digital representations of vehicle panels, enabling precise comparisons before and after repairs. This technology ensures that every curve, contour, and angle is captured, facilitating an exact match during the reconstruction process.

Furthermore, collision repair services often employ computer-aided design (CAD) software integrated with robotic welding systems. This combination allows for seamless panel alignment and consistent weld quality. By combining these high-tech tools with the expertise of skilled technicians in a reputable auto repair shop or vehicle body shop, the end result is restored vehicles that not only look good but also maintain structural integrity—a testament to the commitment to excellence in crash worthiness restoration.

Ensuring Safety: Techniques for Quality Assessment Post-Restoration

Ensuring safety is paramount during crash worthiness restoration work. After repairs have been made, meticulous quality assessment techniques are essential to verify that the vehicle meets the highest standards of structural integrity and safety. This involves a comprehensive inspection, utilizing advanced tools designed to detect even subtle imperfections or misalignments. For instance, non-destructive testing methods such as ultrasonic wave scanning and infrared thermography can identify hidden damage or residual stress without causing further harm to the restored components.

Automotive restoration, especially for classic cars, demands precision and attention to detail. Vehicle repair services must employ these advanced assessment techniques post-restoration to guarantee that the car not only looks but also drives safely. By adhering to strict quality control measures, restorers can ensure that every part of the crash worthiness restoration process has been executed flawlessly, providing owners with peace of mind on the road.

Crash worthiness restoration is a critical process that requires meticulous attention to detail and precise monitoring. By employing the right tools and techniques outlined in this article, professionals can ensure the accuracy and safety of their work, adhering to stringent industry standards. These essential practices not only guarantee vehicle safety but also maintain the structural integrity and overall quality of crash worthiness restoration work.