Crash worthiness restoration transforms damaged vehicles through skilled craftsmanship and advanced technology, achieving structural integrity and adhering to modern safety standards. The meticulous process includes assessment, repair techniques like paint and dent removal, and final inspection. Innovations like composite materials, CAD design, and 3D printing drive transformations, ensuring vehicles return to pre-crash conditions efficiently and cost-effectively.

In the realm of automotive repair, crash worthiness restoration stands as a testament to modern engineering’s resilience. This article explores real-world examples where vehicles, once involved in collisions, have been expertly transformed into safe and structurally sound machines. We delve into successful case studies, revealing how skilled technicians navigate complex repairs. Additionally, we highlight key steps and industry innovations, including advanced techniques and materials, that ensure vehicles not only look like new but also possess unparalleled crash worthiness.

- Successful Case Studies: Vehicles Transformed

- Key Steps in Restoring Crash Damage Effectively

- Industry Innovations: Modern Techniques and Materials

Successful Case Studies: Vehicles Transformed

In the realm of automotive crash worthiness restoration, several successful case studies stand as testament to the transformative power of skilled craftsmanship and cutting-edge technology. These vehicles, once damaged beyond recognition, have undergone remarkable makeovers, showcasing the industry’s ability to restore them to their former glory, or even elevate them to new standards of excellence. Each case study is a vivid illustration of what meticulous crash worthiness restoration can achieve, combining safety, aesthetics, and functionality.

Autobody repairs in these instances are not merely about fixing dents and cracks; they involve intricate processes that ensure structural integrity while preserving the vehicle’s original design essence. Auto glass repair plays a pivotal role, restoring visibility and enhancing overall safety. Car restoration, when done correctly, goes beyond cosmetic enhancements; it involves meticulous attention to detail, precise adjustments, and sometimes even innovative modifications to meet modern safety standards. These transformed vehicles not only hit the roads with renewed confidence but also serve as vibrant examples of what can be accomplished through dedicated crash worthiness restoration practices.

Key Steps in Restoring Crash Damage Effectively

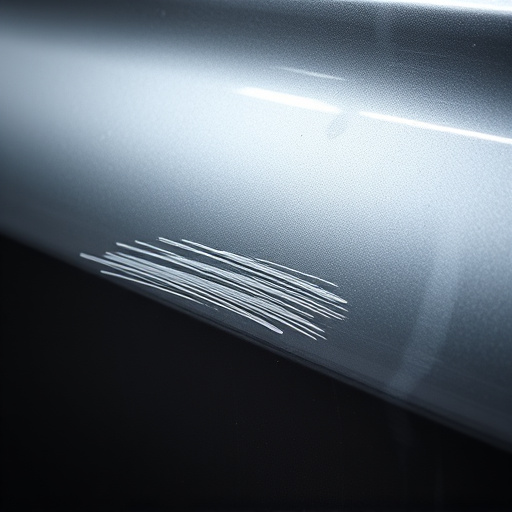

Restoring a vehicle to its pre-crash condition requires a meticulous process that involves several key steps. First, an extensive assessment is conducted to identify the extent of damage, which includes examining the structural integrity and evaluating any cosmetic issues like dents, scratches, or paint chips. This initial phase is crucial for determining the restoration scope and ensuring crash worthiness.

Once the damage is assessed, specialized technicians employ techniques such as vehicle paint repair, car dent removal, and precision body shaping to restore the vehicle’s original appearance. Every effort is made to match the original finish perfectly, maintaining the vehicle’s aesthetic value. After these repairs, a final inspection ensures that all damages have been addressed, and the vehicle meets the highest standards of crash worthiness, ready to hit the road again.

Industry Innovations: Modern Techniques and Materials

The field of crash worthiness restoration has seen significant advancements and innovations over the years, driven by the need to enhance safety standards and reduce vehicle damage post-collisions. Modern techniques and materials are revolutionizing how fleet repair services and automotive repair services address car dent removal and structural integrity. One notable development is the introduction of advanced composite materials, which offer superior strength-to-weight ratios compared to traditional metal panels. These composites can be molded into complex shapes, allowing for precise restoration of vehicle bodies while minimizing weight addition.

Additionally, computer-aided design (CAD) technology and 3D printing have become invaluable tools in crash worthiness restoration. CAD systems enable detailed modeling of damaged components, facilitating accurate measurements and material selection for repairs. 3D printing, on the other hand, enables the rapid creation of custom parts, reducing lead times and costs associated with traditional manufacturing methods. These industry innovations not only ensure that vehicles return to their pre-crash conditions but also contribute to more efficient fleet repair services, making crash worthiness restoration a seamless and effective process for automotive repair services.

Crash worthiness restoration is not just about repairing vehicles; it’s about ensuring safety, stability, and structural integrity for future journeys. By employing modern techniques and materials, as exemplified in successful case studies and highlighted in key steps, the industry continues to evolve, offering effective solutions that restore vehicles to their pre-crash condition while adhering to stringent safety standards. These advancements underscore the importance of professional crash worthiness restoration in preserving both vehicle value and passenger security.